Wago - Complete Guide

Wago

In the dynamic realm of electrical and automation solutions, one name has consistently stood out for its unwavering commitment to innovation, quality, and progress: Wago. With a storied history that spans decades, Wago has cemented its position as a global leader in electrical interconnection and automation technology. In this comprehensive article, we will embark on a journey through Wago's remarkable evolution, delve into their steadfast core values, and provide a comprehensive exploration of their diverse range of products, including the renowned Wago connectors.

Wagos History

The Wago story began in Minden, Germany, in 1951, when the company's founders laid the groundwork for what would become a trailblazing force in the industry. From its humble origins as a manufacturer of spring clamp terminal blocks, Wago quickly earned a reputation for its innovative prowess. In the early 1970s, the introduction of CAGE CLAMP® technology marked a turning point that revolutionized electrical connections. This groundbreaking method simplified and optimized wiring processes, propelling Wago to the forefront of electrical interconnection solutions.

Wago's Core Values

Wago's enduring success is underpinned by a set of core values that serve as guiding principles for the company's operations:

-

Innovation: Innovation is not just a buzzword at Wago; it is a driving force. Through continuous research and development, Wago consistently pushes boundaries, forging new paths, and redefining industry standards.

-

Quality: Wago's commitment to quality is resolute. Meticulous attention to detail, stringent quality control, and adherence to globally recognized standards ensure that each Wago product embodies the epitome of reliability and performance.

-

Sustainability: Environmental responsibility is deeply ingrained in Wago's ethos. By embracing energy-efficient production methods, utilizing eco-friendly materials, and minimizing their environmental footprint, Wago contributes to a more sustainable future.

-

Customer-Centric Approach: Wago places the customer at the core of their endeavors. By empathetically understanding customer needs and challenges, Wago develops solutions that provide tangible value and address real-world requirements.

Exploring Wago's Extensive Product Ranges

Wago's product portfolio encompasses an array of solutions that cater to diverse industries and applications. Among their notable offerings are:

-

Wago Connectors: The cornerstone of Wago's legacy, these connectors leverage the revolutionary CAGE CLAMP® technology. This ingenious spring clamp connection method streamlines wiring, augments reliability, and reduces installation time. Wago connectors, available in a variety of styles including terminal blocks, PCB connectors, and pluggable connectors, find applications in building automation, industrial automation, and renewable energy sectors.

-

I/O Systems: Wago's I/O systems orchestrate seamless communication between field devices and controllers. These systems play an instrumental role in industrial automation and process control, facilitating efficient data exchange and precise control of machinery and processes.

-

Automation Technology: Wago's comprehensive suite of automation solutions encompasses controllers, software platforms, and visualization tools. These technologies empower businesses to optimize processes, enhance efficiency, and remain competitive in an ever-evolving market landscape.

-

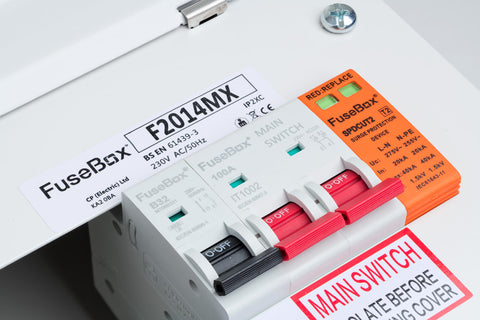

Electrical Interconnection Solutions: Beyond connectors, Wago offers an extensive range of electrical interconnection solutions, including terminal blocks, cable and wire management systems, and surge protection devices. These offerings cater to the intricate wiring demands of modern industries.

Conclusion

Wago's transformative journey from a modest spring clamp terminal block manufacturer to a global trailblazer of innovation is a testament to their unwavering commitment to excellence. The fusion of a storied history steeped in innovation, unwavering core values, and a diverse product portfolio tailored to multifaceted industries has solidified Wago's position as a catalyst for change in the realm of electrical interconnection and automation technology. As industries continue to evolve and technology advances, Wago remains a steadfast ally for enterprises seeking steadfast, efficient, and cutting-edge solutions for their connectivity and automation needs.

Wago FAQ

Yes, WAGO connectors are legal for use in the UK. They comply with British and European electrical standards and regulations, making them a legitimate choice for electrical connections.

Absolutely. WAGO wire connectors, often known for their reliability and convenience, are compliant with relevant safety standards and are widely accepted for use in various electrical applications.

WAGO connectors are typically not used on standard electrical sockets. They are more commonly employed for connecting wires and cables in junction boxes, distribution boards, and control panels.

Yes, many professional electricians rely on WAGO connectors for their efficient and secure wire connections. WAGO's reputation for quality and ease of use has made them a popular choice among professionals.

Electricians often hold WAGO connectors in high regard due to their time-saving benefits, reliable connections, and versatility in various applications.

The number of wires a WAGO connector can accommodate depends on the specific model. Various WAGO connectors are designed to handle different wire capacities, ensuring safe and secure connections.

WAGO connectors can be used to extend a ring main, but proper techniques and adherence to electrical regulations must be followed to ensure safety and compliance.

While WAGO connectors are designed for secure connections, they are generally meant to be enclosed within junction boxes or enclosures for protection against environmental factors and accidental contact.

The ampacity of a WAGO connector varies depending on the model and size. WAGO connectors are available in a range of amp ratings to accommodate different current loads.

Yes, Wagoboxes are designed for installation within walls and ceilings, allowing for plastering over. However, following proper installation guidelines is essential to ensure a secure and code-compliant installation.

WAGO connectors are available in various sizes and specifications, allowing them to handle a wide range of current loads. The specific ampacity depends on the particular WAGO model.

Yes, daisy chaining (connecting multiple WAGO connectors in series) is possible for certain applications, but it's important to adhere to electrical codes and guidelines to ensure proper and safe connections.

Wago 221 connectors are designed for single-use connections. Reusing them may compromise the integrity of the connection and is not recommended for safety reasons.